Introduction

Spain Tactile Sensors Market, a leading agricultural powerhouse in Europe, renowned for its high-quality fruit production, is increasingly embracing technological advancements to enhance efficiency, reduce labor costs, and improve the quality of its yields. Among these transformative technologies, tactile sensors are emerging as a game-changer, particularly in the delicate processes of fruit harvesting and stringent quality control. This article delves into the burgeoning role of tactile sensors in Spanish agriculture, focusing on their revolutionary impact on how fruits are harvested, assessed, and ultimately brought to market.

The Challenges of Traditional Fruit Harvesting and Quality Control in Spain

Traditional fruit harvesting in Spain relies heavily on manual labor, a physically demanding and often time-sensitive process. This approach faces several challenges:

Labor Shortages: The agricultural sector across Europe, including Spain, is grappling with increasing labor shortages, making it difficult and expensive to secure a sufficient workforce during peak harvesting seasons.

Harvesting Inefficiencies: Manual harvesting can be inconsistent, leading to damage to the fruit and varying levels of maturity in the harvested batch.

High Labor Costs: Labor constitutes a significant portion of the overall production cost, impacting the profitability of fruit farming.

Subjectivity in Quality Control: Traditional quality control often involves manual inspection, which can be subjective, inconsistent, and time-consuming, potentially leading to variations in the quality of fruit reaching consumers.

Post-Harvest Losses: Damage during manual harvesting and inefficient quality sorting can contribute to significant post-harvest losses.

Tactile Sensors: Providing the "Sense of Touch" to Agri-Robotics

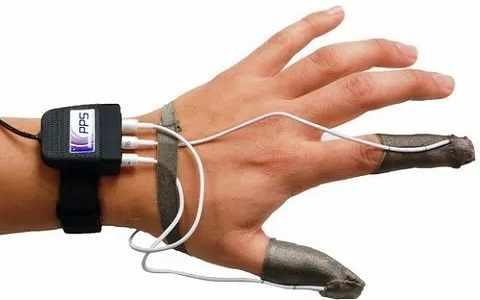

Tactile sensors, devices capable of detecting and measuring physical interactions such as pressure, force, texture, and slippage, offer a sophisticated solution to many of these challenges. By providing robots and automated systems with a sense of "touch," they enable more delicate and precise interaction with fragile fruits.

Revolutionizing Fruit Harvesting with Tactile Intelligence

The integration of tactile sensors into agricultural robots is paving the way for automated fruit harvesting in Spain. Here's how:

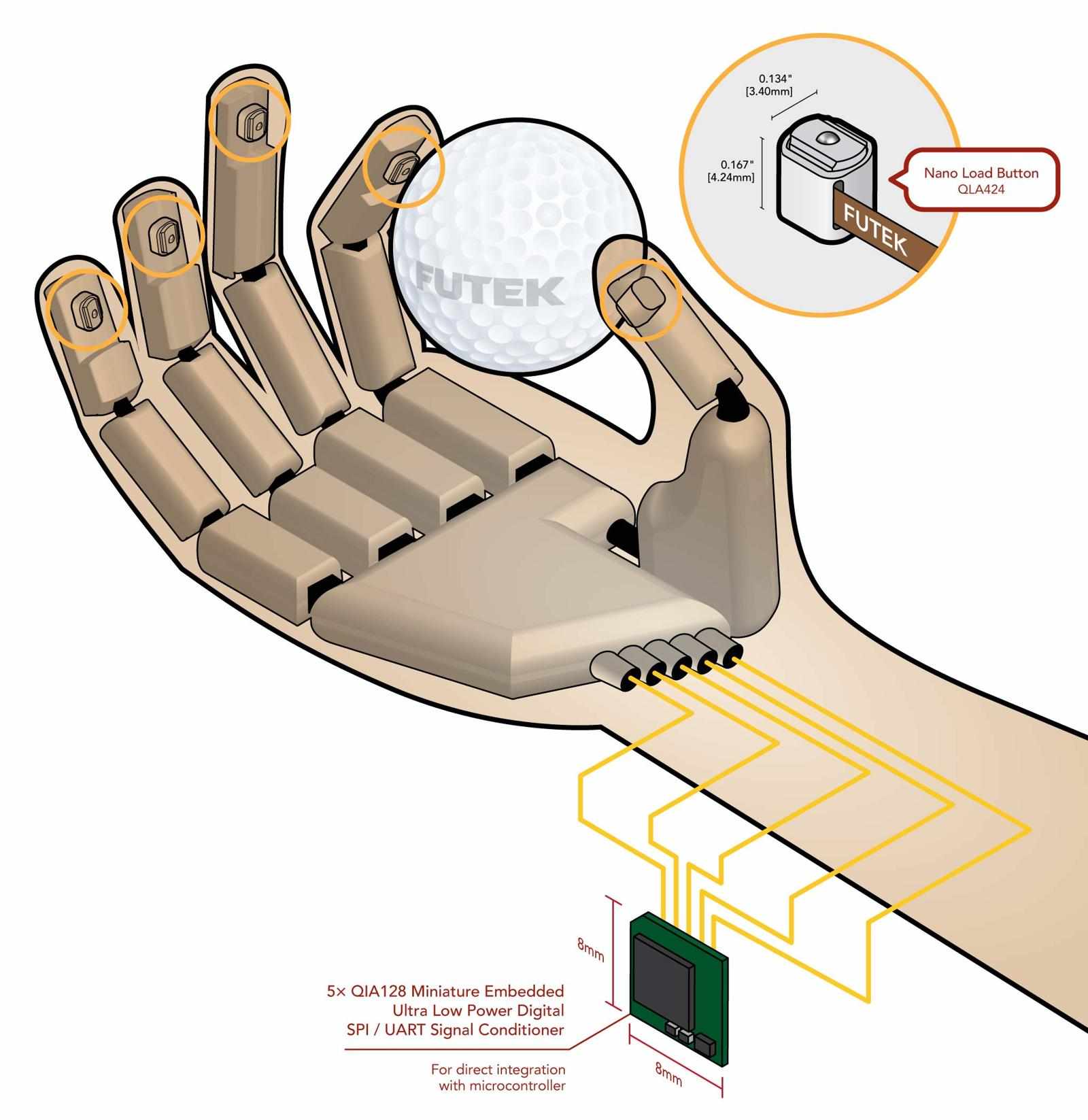

Gentle Grasping and Manipulation: Robotic arms equipped with advanced tactile sensors can "feel" the shape, size, and firmness of individual fruits. This allows them to apply the precise amount of force needed to detach the fruit without causing bruising or damage, mimicking the dexterity of a human hand but with greater consistency.

Selective Harvesting Based on Ripeness: Tactile sensors, often coupled with vision systems, can help robots assess fruit ripeness by detecting subtle changes in firmness. This enables selective harvesting, ensuring that only fruits at their optimal maturity are picked, leading to higher quality yields.

Increased Harvesting Speed and Efficiency: Automated harvesting systems can operate continuously, day and night, significantly increasing the speed and efficiency of the harvesting process compared to manual labor. This helps farmers meet tight harvesting windows and reduce reliance on a large seasonal workforce.

Accessing Difficult-to-Reach Areas: Robots equipped with tactile sensors can be designed to navigate complex orchard structures and reach fruits in high or awkward positions that are challenging for human pickers.

Data Collection for Yield Optimization: The tactile sensors and associated robotic systems can collect valuable data on the location, size, and firmness of harvested fruits, providing insights for yield mapping and optimization strategies for future growing seasons.

Examples of Tactile Sensor Applications in Fruit Harvesting:

Soft Robotic Grippers: Robots with soft, compliant grippers integrated with tactile sensors can conform to the irregular shapes of fruits like strawberries, raspberries, and peaches, ensuring a secure yet gentle grasp.

Force-Controlled End-Effectors: Tactile force sensors on robotic end-effectors allow for precise control of the gripping force applied to fruits like apples and oranges, preventing damage during detachment and handling.

Slip Detection Sensors: These sensors can detect when a fruit is slipping from the robot's grasp, allowing the system to adjust its grip force in real-time, minimizing drops and losses.

Enhancing Quality Control with the Sense of Touch

Beyond harvesting, tactile sensors are playing a crucial role in revolutionizing quality control processes in the Spanish fruit industry:

Automated Firmness and Texture Assessment: Tactile sensors can be integrated into automated sorting and grading systems to objectively assess the firmness and texture of fruits. This provides a more consistent and reliable measure of quality compared to subjective manual assessment.

Detection of Bruises and Damage: Advanced tactile sensors can detect subtle variations in pressure and surface irregularities, enabling the identification of bruises and other forms of damage that might not be immediately visible to the human eye.

Internal Quality Prediction: Research is exploring the potential of using tactile sensors, in conjunction with other sensing modalities like acoustics, to non-destructively assess internal fruit quality parameters such as sugar content and maturity.

Traceability and Data Logging: Data from tactile sensors used in quality control can be integrated into traceability systems, providing a detailed record of the quality attributes of each batch of fruit as it moves through the supply chain.

Reducing Food Waste: By enabling more accurate and efficient sorting, tactile sensors can help reduce the amount of high-quality fruit that is unnecessarily discarded due to subjective or inefficient quality control processes.

Emerging Innovations in Tactile Sensors for Spanish Agriculture

The field of tactile sensors is constantly evolving, with several emerging innovations holding significant promise for Spanish agriculture:

High-Resolution Tactile Arrays: These sensors offer a detailed "tactile image" of the fruit surface, enabling the detection of very subtle defects and textural variations.

Bio-Inspired Tactile Sensors: Researchers are drawing inspiration from biological systems, such as the human fingertip, to develop highly sensitive and adaptable tactile sensors.

Wireless Tactile Sensors: The development of wireless tactile sensors will simplify integration into robotic systems and allow for real-time data transmission and remote monitoring.

Energy-Harvesting Tactile Sensors: Self-powered tactile sensors that harvest energy from the environment or the interaction itself could lead to more sustainable and autonomous agricultural robots.

Integration with AI and Machine Learning: Combining tactile sensor data with artificial intelligence and machine learning algorithms will enable more sophisticated analysis of fruit characteristics and improve the decision-making capabilities of automated harvesting and quality control systems.

The Spanish Agri-Tech Ecosystem: Fostering Innovation

Spain boasts a vibrant and growing agri-tech ecosystem, with research institutions, technology companies, and agricultural organizations collaborating to develop and implement innovative solutions like tactile sensing. Government initiatives and funding programs are also playing a crucial role in supporting the adoption of advanced technologies in the agricultural sector. This supportive environment is essential for the continued integration of tactile sensors into Spanish fruit farming practices.

Challenges and Future Outlook

Despite the immense potential, the widespread adoption of tactile sensors in Spanish agriculture faces certain challenges:

Cost of Implementation: The initial investment in robotic harvesting systems and advanced quality control equipment equipped with tactile sensors can be significant for some farmers.

Technical Complexity: Integrating and maintaining these sophisticated systems requires specialized knowledge and expertise.

Adaptability to Diverse Fruit Types and Orchard Conditions: Developing tactile sensing solutions that can effectively handle the wide variety of fruits grown in Spain and adapt to different orchard layouts and environmental conditions is an ongoing challenge.

Data Management and Integration: Effectively managing and integrating the large volumes of data generated by tactile sensors and robotic systems is crucial for realizing their full potential.

Conclusion

The future of tactile sensors in Spanish agriculture is bright. As the technology matures, costs are expected to decrease, and user-friendly interfaces will become more prevalent. Continued research and development, coupled with strong collaboration within the Spanish agri-tech ecosystem, will drive further innovation and adoption. Tactile sensors are poised to become an indispensable tool for Spanish fruit farmers, enabling them to achieve greater efficiency, higher quality yields, reduced labor dependence, and enhanced sustainability in their operations, solidifying Spain's position as a leading producer of premium quality fruits in the global market.

Write a comment ...